Further Images Of Maximator’s New Factory In Nordhausen

Maximator’s new H2 Factory with a Fuel Cell Truck

Mathias Kurras presents our new hydrogen flagship.

Maximator are working to advance our ideas and developments for mobility solutions.

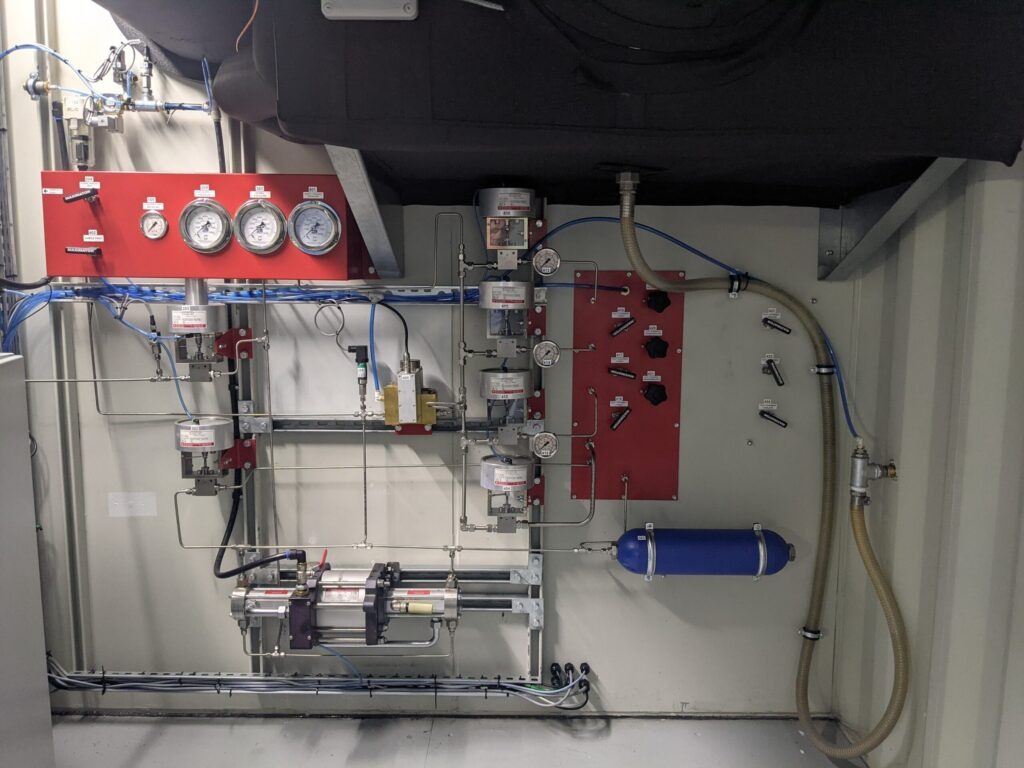

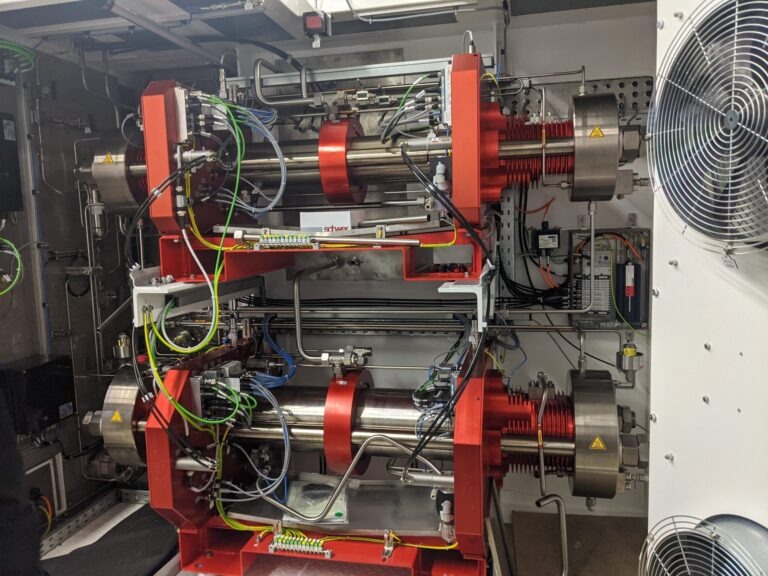

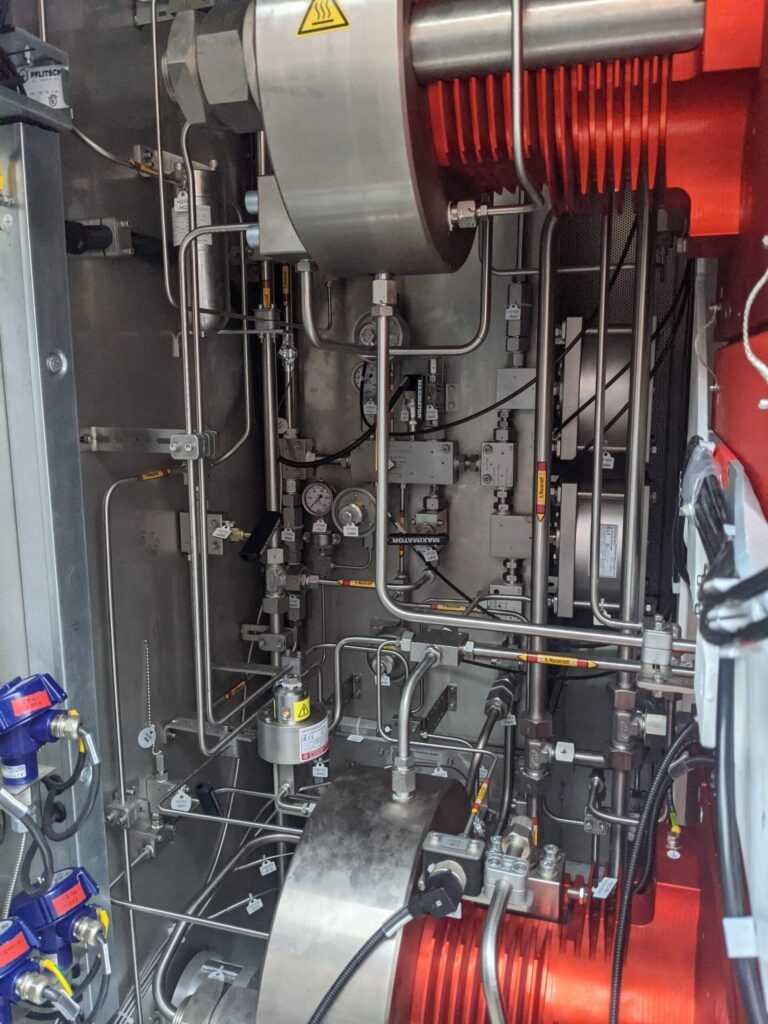

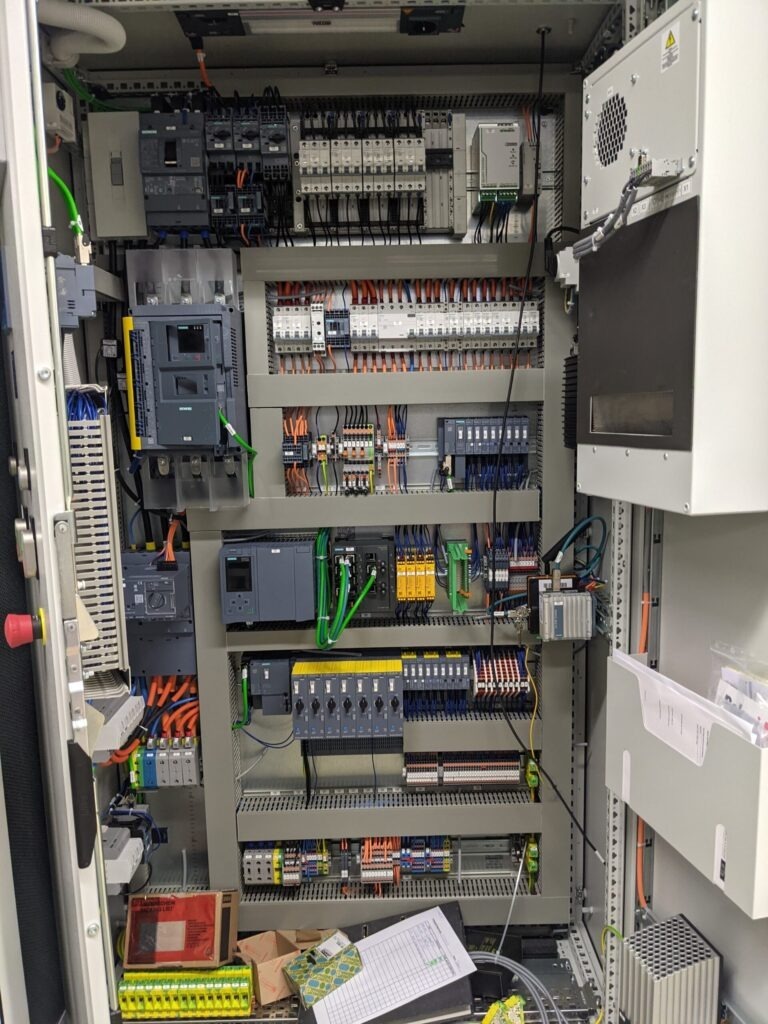

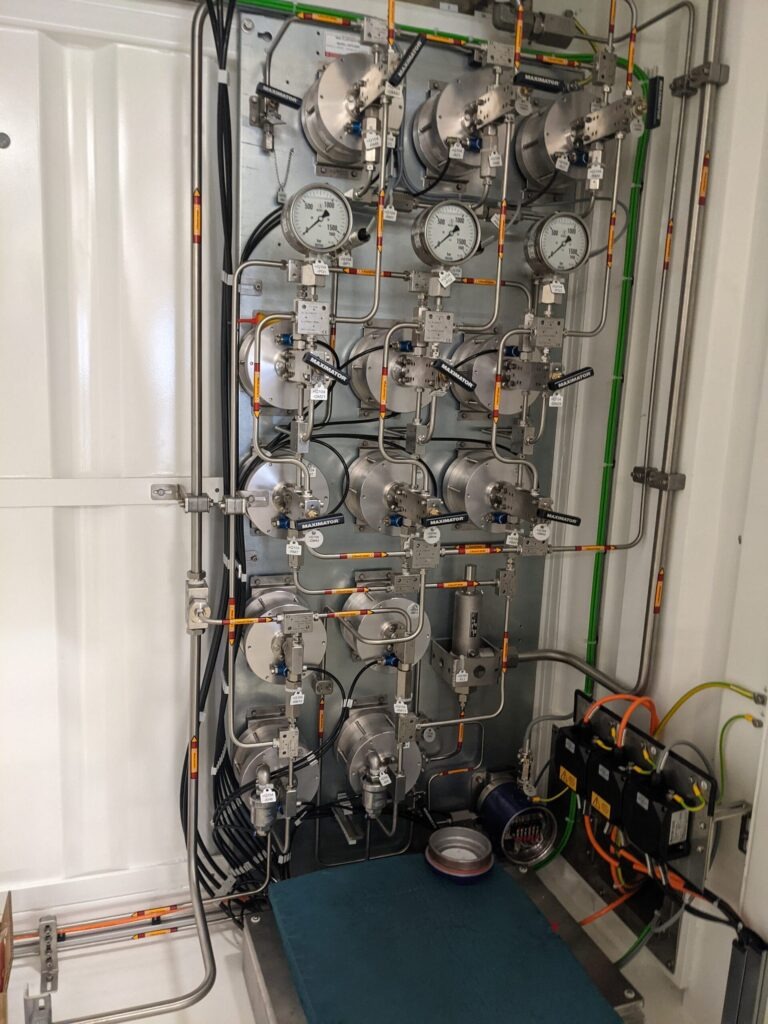

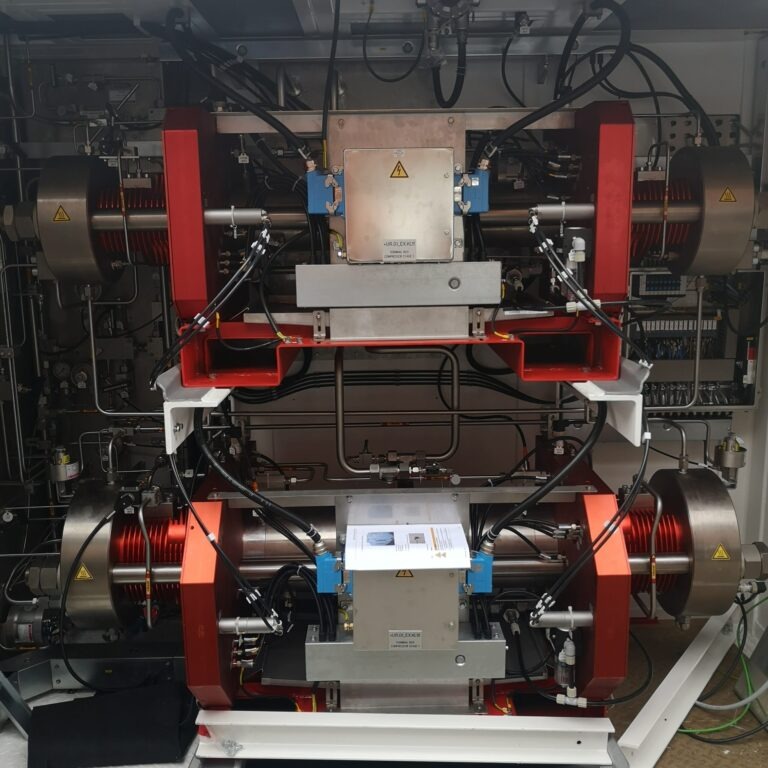

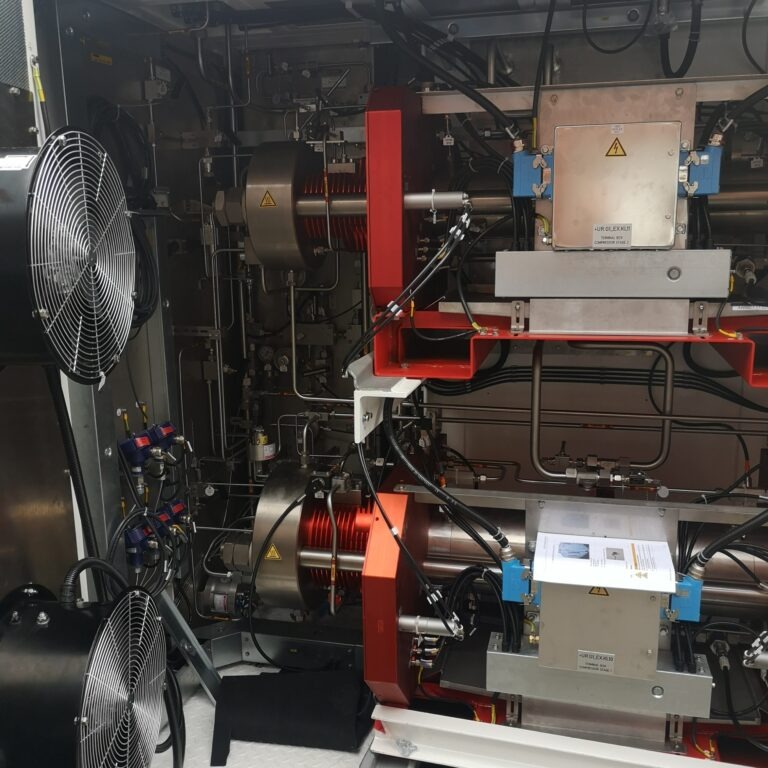

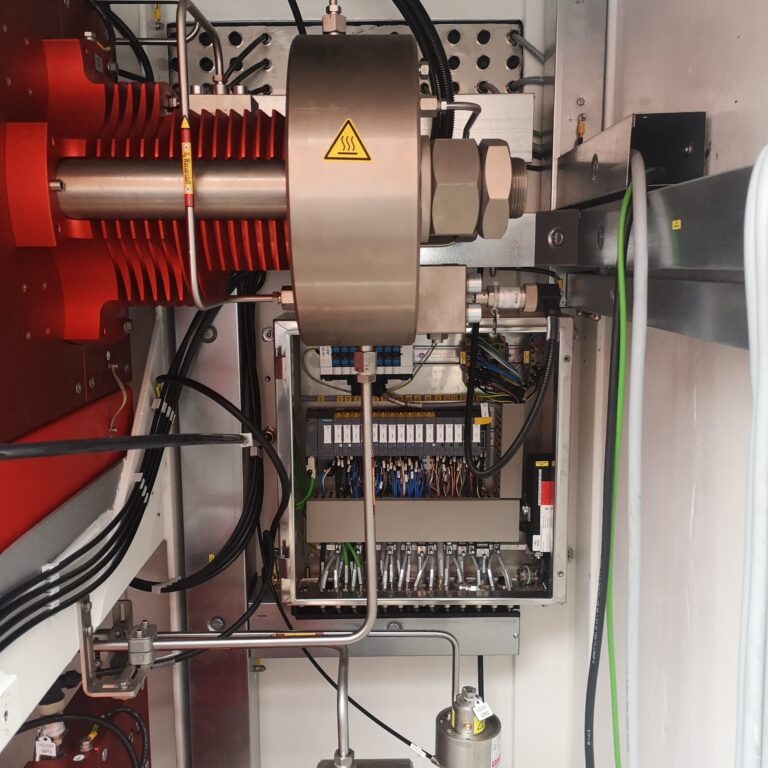

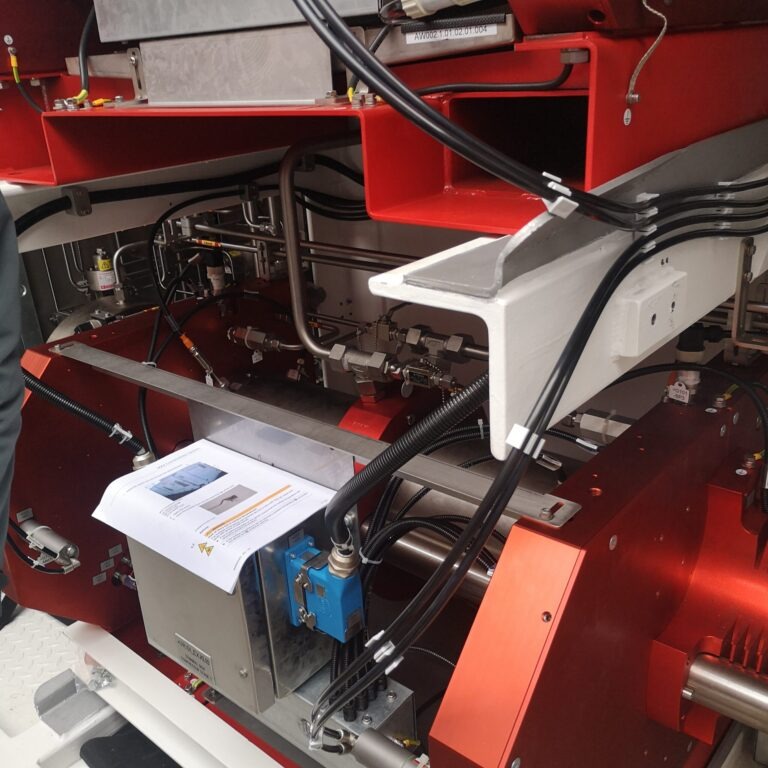

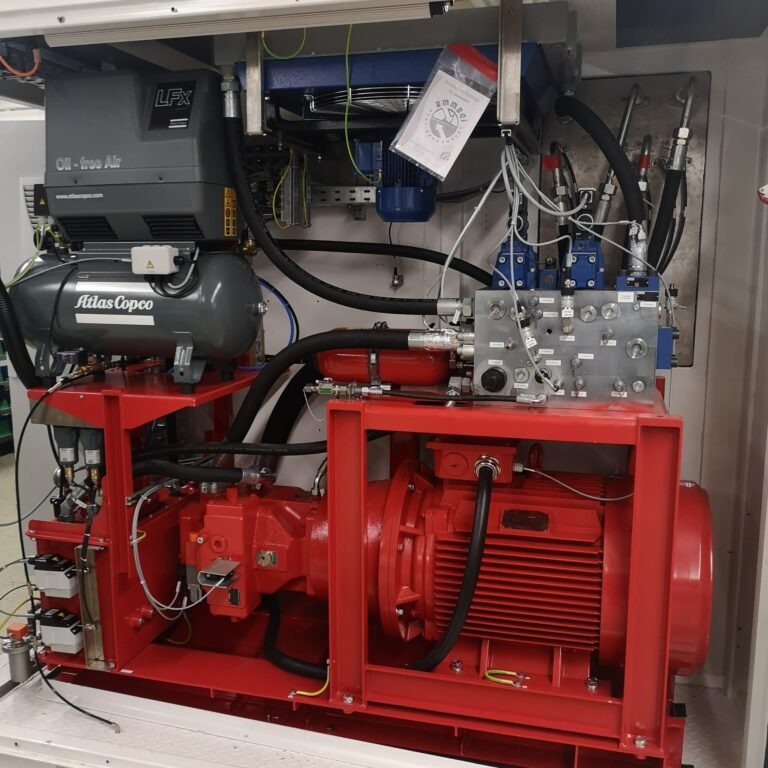

With this in mind, Mathias Kurras presents our new hydrogen flagship – The first of our factories devoted to Hydrogen systems for refuelling.

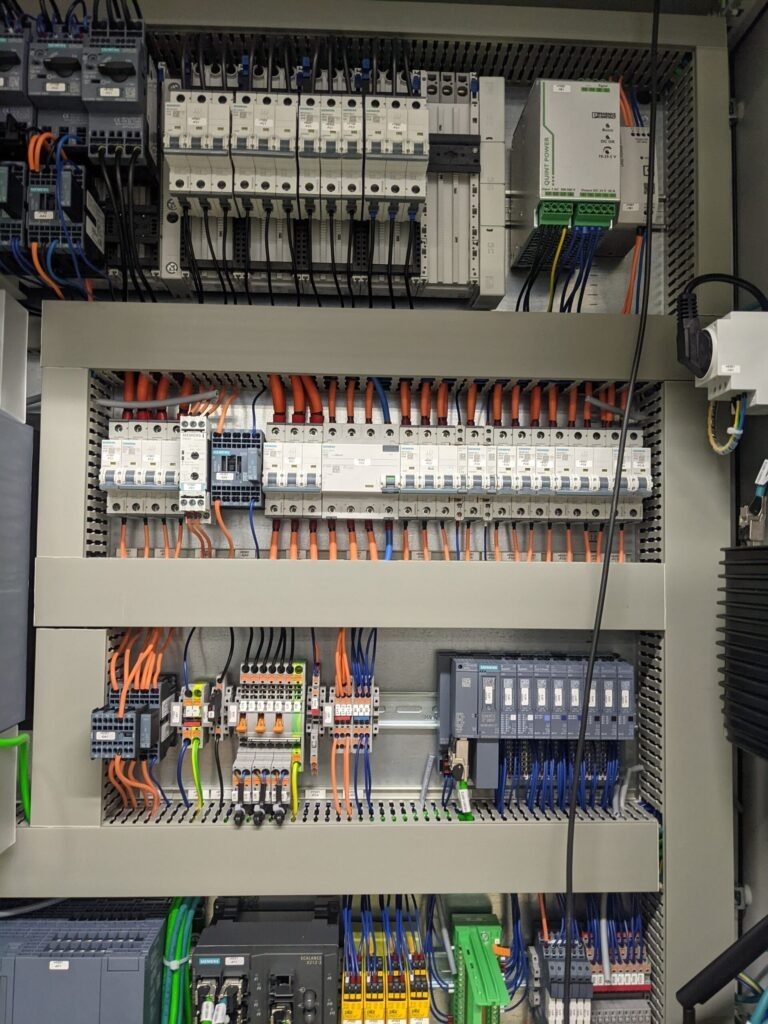

Maximator UK offers systems from across the Maximator companies for Hydrogen. From full scale “highway” refuelling station systems such as those made in Mr. Kurras’ factory, to systems for small fleet operators to pilot and test equipment for Hydrogen.

View our Hydrogen Products HERE

#fueledbyhydrogen #maximatoruk #greenenergy #maximator